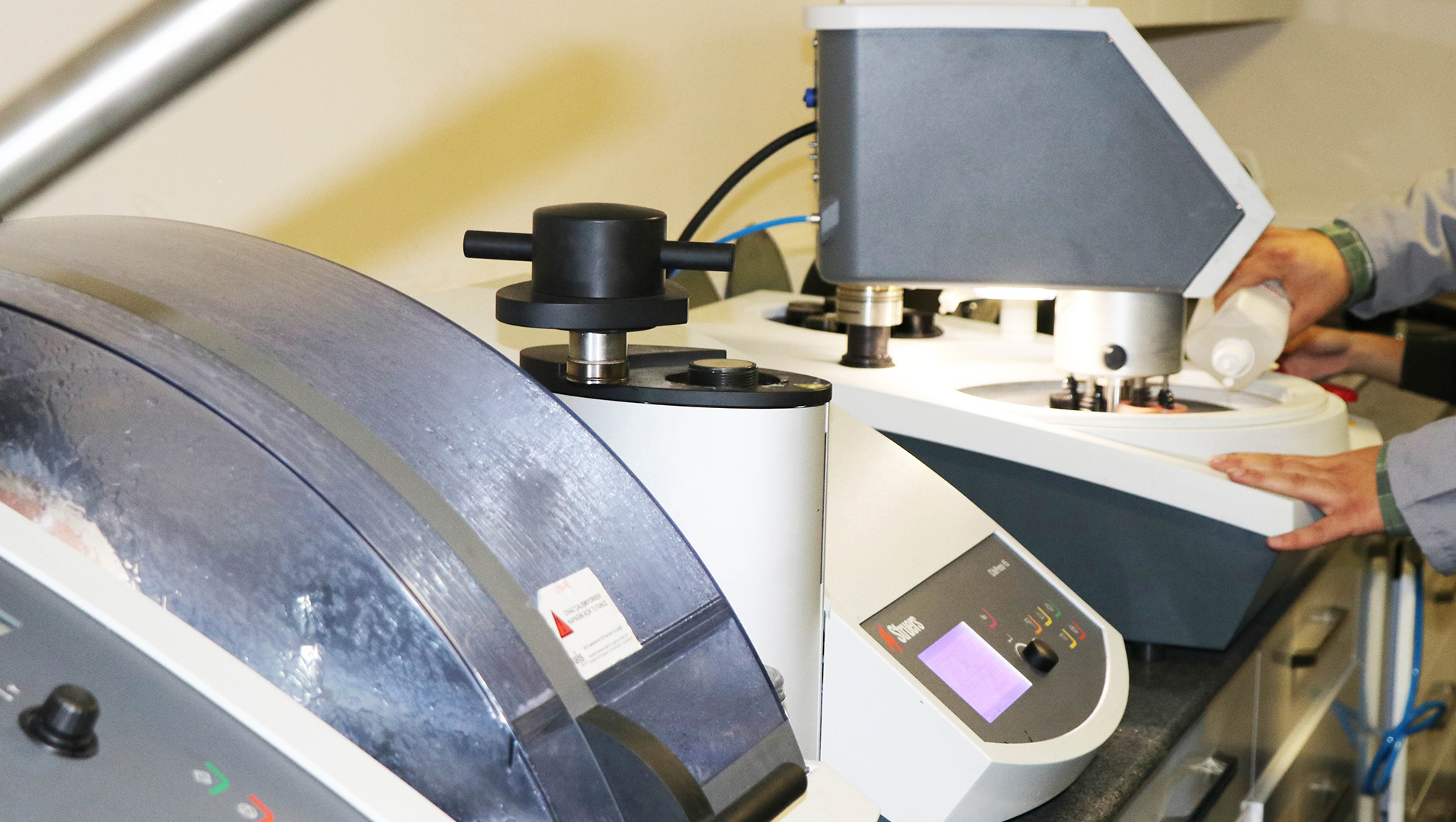

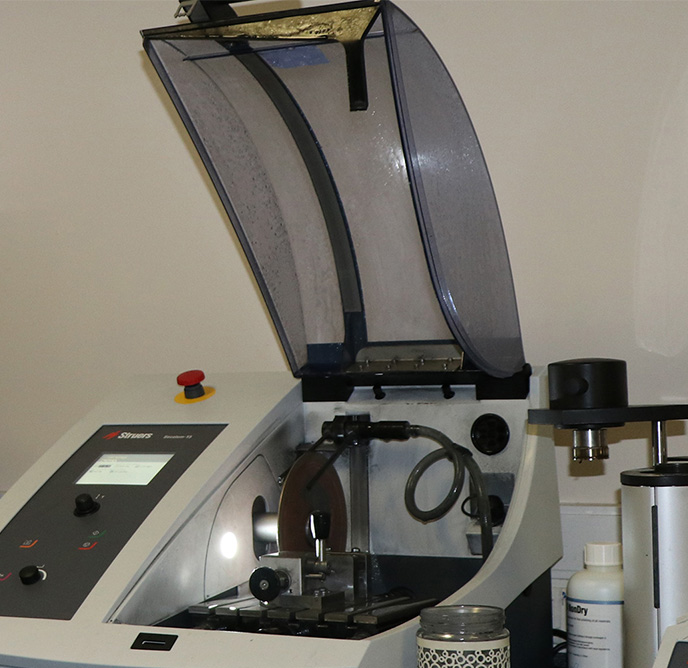

Quality Laboratory

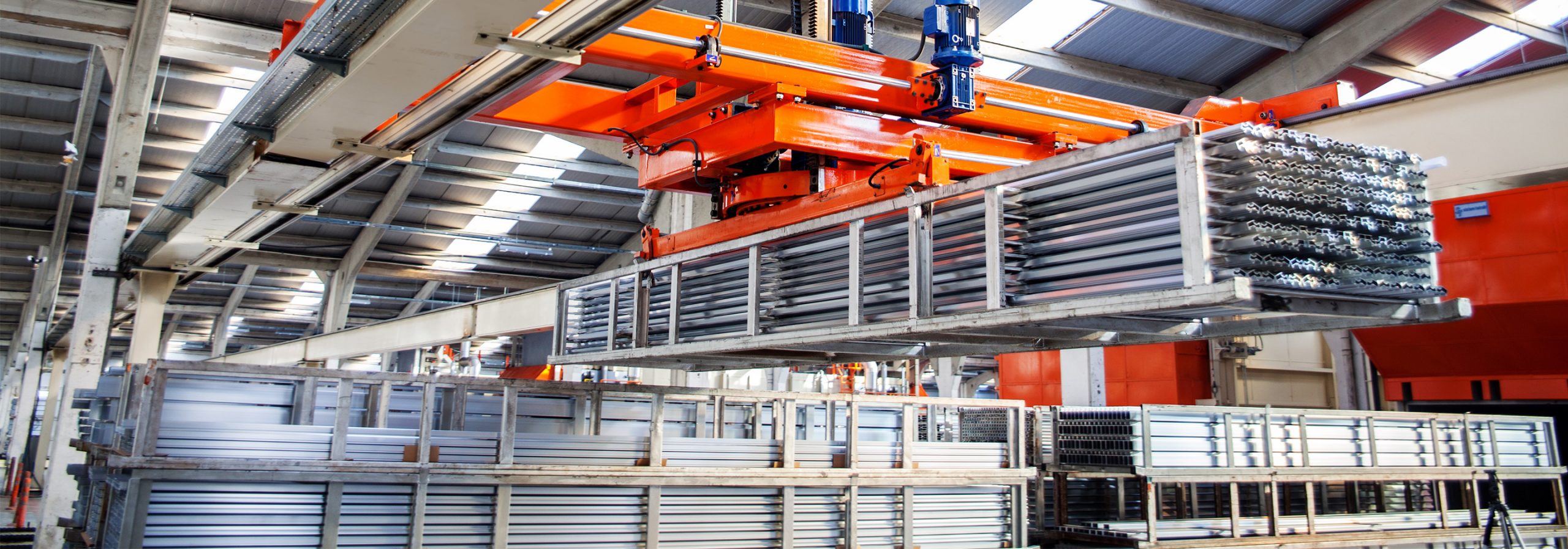

Sensitive productions are made within the scope of international standards and customer special requests. Our production capabilities, product performances are documented by the quality certificates we have received and customer audits. Our products are sent to all continents around the world and are produced to meet country-specific standards.

In line with the principle we have determined, we continue to provide the best service in terms of quality in our products made in our fully integrated facility.

Our company, which has IATF 16949, ISO 9001, ISO 14001, ISO 45001, ISO 27001 quality management system certificates, carries out and inspects its quality management processes with integrated management systems.

Our New Product Commissioning process is carried out by expert staff, and customer demands are examined and evaluated in detail. During the commissioning process of the New Product, the proposals are examined by the project team, which is collected specifically for the project, and the needs such as investment plans, control fixture, apparatus and personnel are determined, and project investments are made.