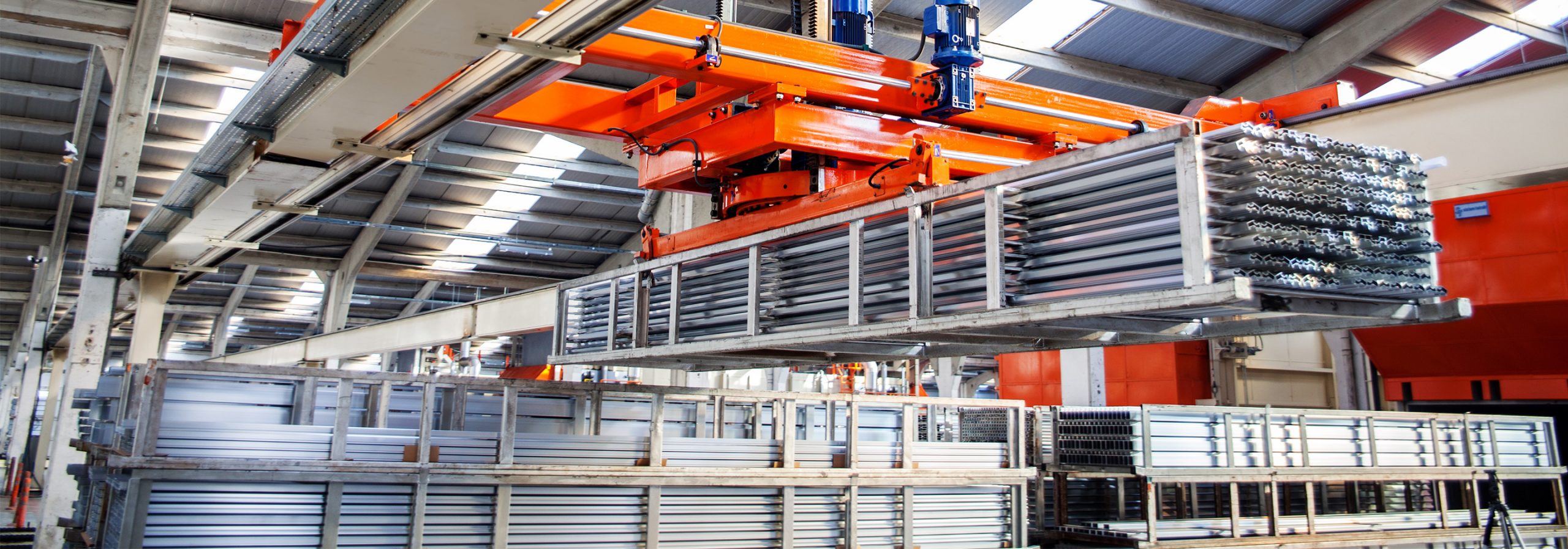

In our extrusion lines, aluminum profiles are manufactured for various sectors and purposes. Extrusion process can be summarized as forcing a heated aluminum billet to pass through a die so that the aluminum that exits the die takes a particular shape as it stretches out as a profile. Aluminum profile extrusion is a sensitive process measured in microns. Sistem is a specialist in tailor made aluminium profiles.

Specific component design, based on in-depth knowhow and supported by advanced IT infrastructure, enables us to build bespoke products that are individual to customer specifications. Our experience and resources ensure delivery in the most cost and time efficient way.

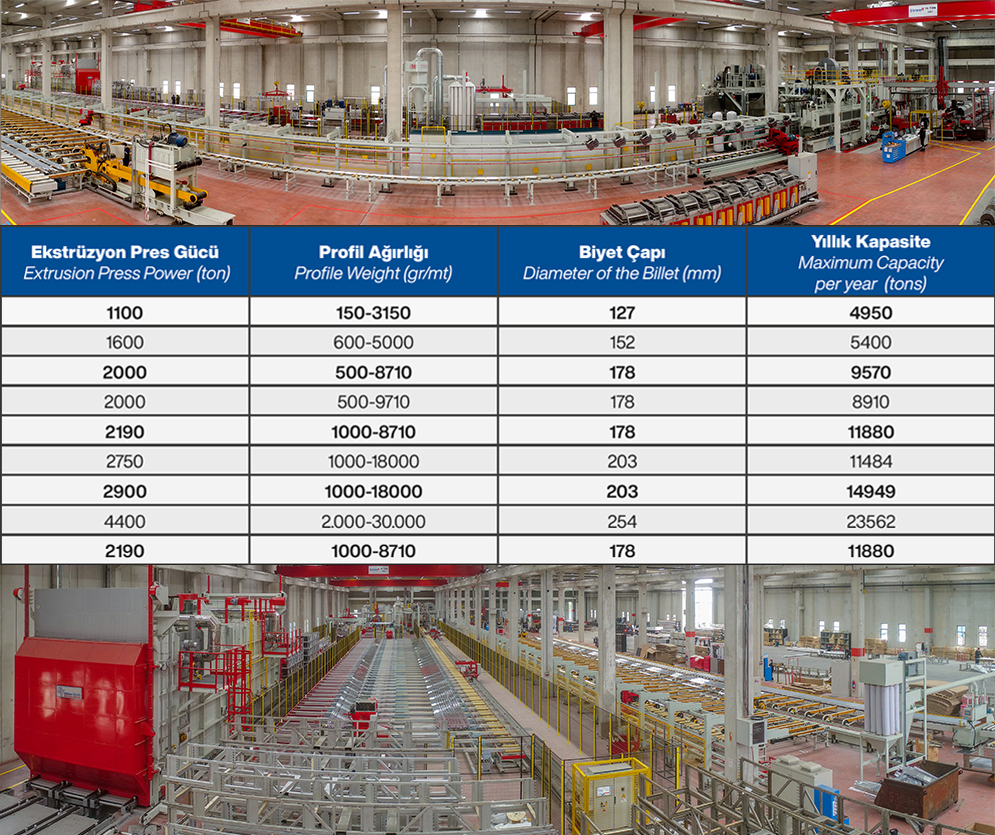

In our extrusion department, there are 9 press lines that we can produce profiles up to 14 meters long. The aluminum billets used in our extrusion lines are first class. In our production, besides 1xxx, 5xxx and 6xxx series alloys, special alloyed profiles can also be manufactured.