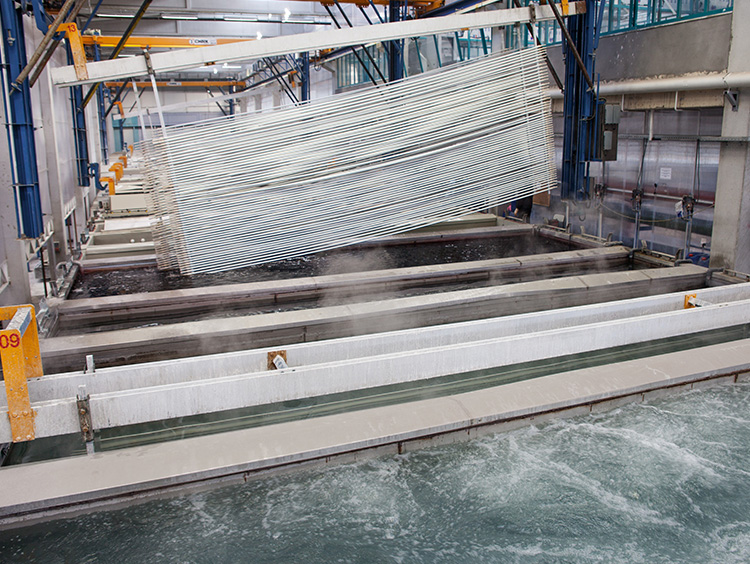

Anodizing is a method used to change the surface chemistry of Aluminum products. It protects the surface of aluminum products against corrosion, provides an aesthetic appearance, gives resistance to scratches and is one of the most durable surface coating techniques available.

Anodizing

The Color Chart:

The processes carried out in our anodizing facility are under the guarantee of European QUALANOD specification and TSE with features such as lifetime, UV resistance and color permanence. Our production facility has the latest technology and profiles between 2000 mm and 7500 mm can be processed. In addition to our standard colors, optional color studies are carried out in our pools.

Our anodizing facility is the industry’s leading surface treatment facility with an annual capacity of 24,000 tons and fully automated system. Our company, which is sensitive to the environment and human health; Meets ROSH and REACH requirements.

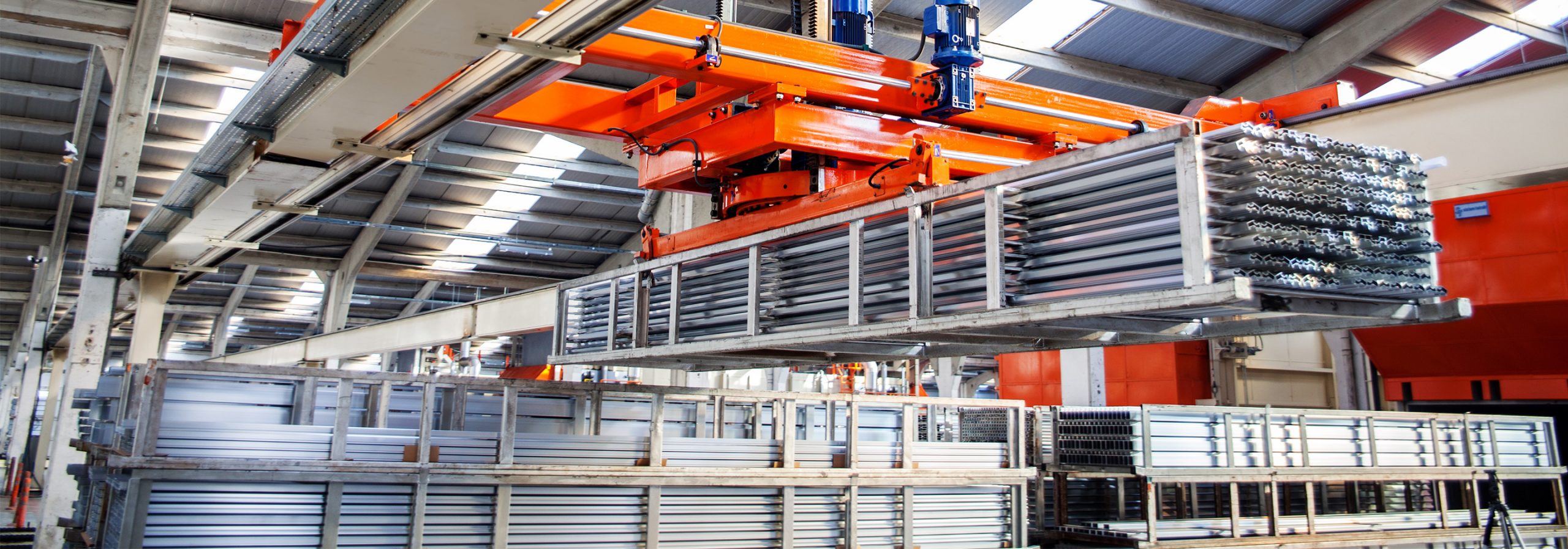

The Special (Hard) Anodizing Facility:

The weight of special and hard anodized aluminum profiles and parts is much less than stainless steel. In addition, processing effort and cost is more advantageous than stainless steel. Therefore; It is preferred to use special or hard anodized aluminum materials in many areas such as machine parts, defense industry, aviation and automotive against corrosive liquids.

Our Special Anodizing Facility, which we have completed in 2021, has an annual anodizing capacity of 12.000.000 pieces. In this facility; Hard and special anodizing processes can be performed with 5 to 80 µm thickness, up to 400 HV hardness and with a gloss value in the range of 500-1000 according to demand.